Table of Contents

ToggleWhat is Sustainable Packaging?

The e-commerce industry has experienced exponential growth over the past few years, and with it comes an increase in packaging waste. As consumers become more environmentally conscious, businesses are seeking innovative solutions to minimize their ecological footprint without compromising product protection or customer satisfaction. Here are ten groundbreaking innovations in sustainable packaging designed specifically for e-commerce applications.

This shift has moved sustainable packaging from a niche “green” marketing tactic to a core strategic imperative. For modern e-commerce businesses, it’s no longer just about minimising an ecological footprint; it’s about future-proofing the brand, building unshakeable customer loyalty, and creating operational efficiencies that benefit both the planet and the bottom line.

Sustainable packaging is a complex, multi-faceted challenge that balances three critical pillars: product protection (ensuring the item arrives undamaged), customer experience (creating an unboxing moment that delights), and environmental responsibility (minimizing waste and using renewable or circular materials). The following ten innovations represent the vanguard of this movement, offering practical, scalable solutions designed specifically for the unique demands of the e-commerce supply chain.

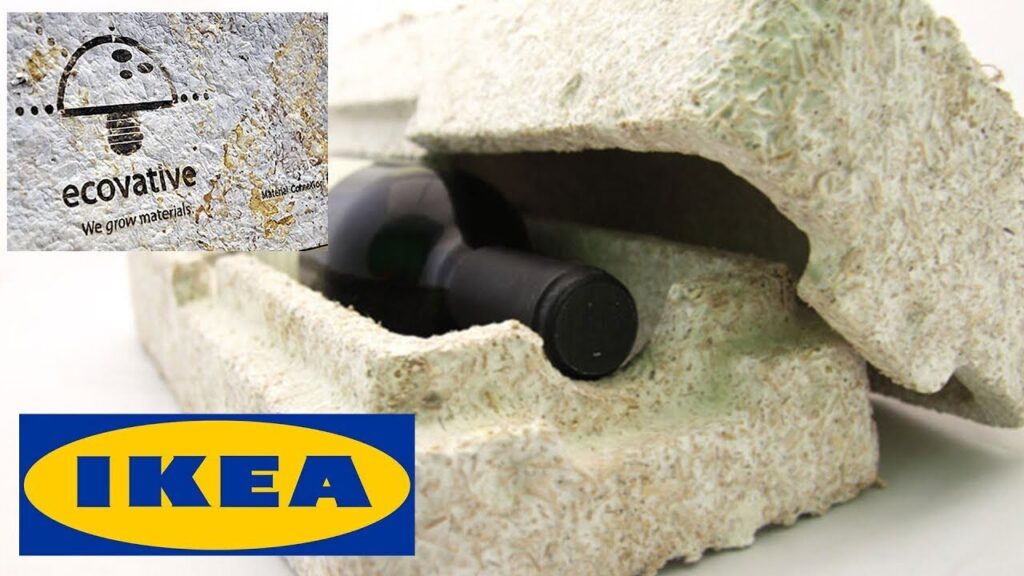

#1 Mushroom-Based Packing Materials

The quest to replace polystyrene foam (Styrofoam) has long been a holy grail in sustainability. Companies like Ecovative Design have pioneered a remarkably elegant solution by harnessing the power of mycelium, the intricate, root-like network of fungi.

The process is a lesson in bio-mimicry: agricultural waste products, such as corn stalks or hemp hurds, are cleaned and placed into a mould shaped like the desired protective packaging. Mycelium is then introduced and allowed to grow through this waste, acting as a natural, self-assembling binder. In a matter of days, it forms a solid, robust structure that is then heat-treated to stop the growth.

The result is a packaging material that is not only fully home-compostable and biodegradable but also provides exceptional cushioning and protective properties. It can be custom-grown to fit specific products perfectly, eliminating the need for excessive void fill and reducing material usage.

Unlike synthetic foams, which are derived from petroleum and can persist in landfills for centuries, mycelium packaging will naturally decompose in a matter of weeks when added to soil, returning nutrients to the earth. This innovation transforms waste into a high-value, protective resource, creating a truly circular model.

#2 Seaweed-Derived Packaging Films

Single-use plastic films and sachets are among the most pernicious forms of packaging pollution, particularly in marine environments. Startups like NotPla (standing for “Not Plastic”) are tackling this problem head-on by using one of the world’s most abundant and renewable resources: brown seaweed.

Seaweed requires no freshwater, fertiliser, or land to grow; it absorbs CO2 as it grows, making it a carbon-positive raw material. The resulting material is a flexible, transparent, and biodegradable film that can be used for a variety of applications, from protective pouches to food-grade condiment sachets.

The most groundbreaking property of seaweed-based films is their decomposition rate. While a conventional plastic bag may take hundreds of years to break down, a NotPla film decomposes naturally in soil in a matter of weeks.

Even more impressively, it dissolves in water within hours, posing zero harm to marine life if accidentally ingested. This presents a revolutionary solution for water-soluble products and offers a viable path away from the plastic films that currently dominate the e-commerce landscape for small, non-fragile items.

Image Source: Material District

#3 Starch-Based Peanuts in Sustainable Packaging

For decades, the iconic polystyrene packing peanut has been a symbol of e-commerce waste—static-clingy, messy, and environmentally persistent. Starch-based peanuts offer a direct, high-performance alternative. Typically derived from corn, wheat, or potato starch, these peanuts provide similar protective, void-fill capabilities but with a completely different end-of-life story.

Their key advantage is their solubility. Unlike their plastic counterparts, starch-based peanuts dissolve instantly in water, making disposal as easy as running them under a tap. This also means they pose no threat to wildlife or ecosystems if they escape into the environment. Furthermore, they are compostable and biodegradable.

For the business owner, they offer a dust-free, anti-static packing experience, and because they are made from renewable agricultural sources, they reduce dependency on fossil fuels. This is a prime example of a drop-in replacement that requires no change in warehouse packing processes but delivers a monumental environmental upgrade.

#4 Recycled Carboard Boxes in Sustainable Packaging

While seemingly the most established option, the use of recycled corrugated cardboard remains the most impactful and widely adopted practice in sustainable e-commerce. The choice between virgin and recycled cardboard has profound implications. Manufacturing new cardboard from virgin pulp is energy and water-intensive and contributes to deforestation. In contrast, producing cardboard from post-consumer and post-industrial waste drastically reduces these impacts.

Using 100% recycled content boxes closes the loop on the paper stream, creating a circular economy where old boxes become new ones. This process consumes significantly less energy and water and generates lower greenhouse gas emissions. For brands, it’s a visible, tangible demonstration of their commitment.

Many companies are now also optimizing box sizes through AI-powered software to achieve a “right-size” fit, eliminating unnecessary material use and reducing shipping costs and emissions simultaneously. It’s a foundational practice upon which more advanced innovations can be built.

#5 Plant-Based Inks

The sustainability of a package isn’t just about the substrate; it extends to the inks used for branding and labeling. Conventional printing inks are often petroleum-based and can contain heavy metals and volatile organic compounds (VOCs) that are harmful to both human health and the environment. These toxins can leach into soil and groundwater from landfills.

Plant-based inks, derived from sources like soy, linseed, and corn, offer a safer, more sustainable alternative. They are renowned for producing vibrant colors and are easier to de-ink during the paper recycling process, resulting in higher-quality recycled paper. By choosing plant-based inks, a brand ensures that its entire packaging footprint, down to the very ink, aligns with its environmental values, preventing toxic leakage and supporting the recyclability of its materials.

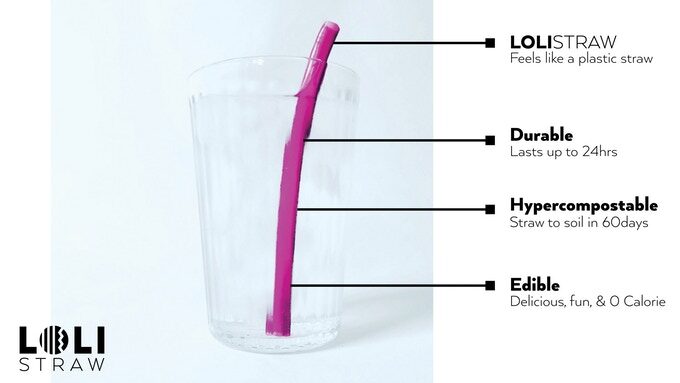

#6 Edible Packaging to Promote Sustainable Packaging

Pushing the boundaries of sustainability, some visionary companies are developing edible packaging. This innovation fundamentally rethinks the purpose of packaging, transforming it from waste into a consumable or a instantly compostable material. Companies like Loliware have created hyper-compostable cups, straws, and even flexible films from seaweed and other organic materials.

Imagine receiving a shipment of protein bars where the inner wrapper is edible, or a box of coffee where the protective pouches dissolve in your compost bin within days. While still a nascent field, edible packaging represents the ultimate expression of a zero-waste philosophy. It challenges the very definition of “disposal” and creates a novel, memorable brand experience that powerfully communicates a company’s dedication to innovation and environmental stewardship.

Image Source: Beverage Daily

#7 Reusable Shippers

The most effective way to reduce waste is to eliminate it at the source. This is the principle behind reusable shipping systems. Instead of a single-use cardboard box, products are shipped in durable, engineered containers made from materials like recycled plastics or metals. Companies like Loop (in partnership with major brands) have pioneered this model, where customers receive their goods in a tote that is later collected, cleaned, refilled, and sent out again.

These shippers are designed for dozens, sometimes hundreds, of trips. This model, known as a “closed-loop” system, dramatically reduces the demand for single-use packaging and fundamentally decouples business growth from resource consumption. While the initial logistics and infrastructure require investment, the long-term savings on material costs and the profound positive brand association can be significant competitive advantages.

Image Source: Modern Retail

#8 Air Pillows for Sustainable Packaging

Inflatable air pillows have become a common sight in e-commerce packages, and for good reason. Their primary sustainability benefit lies in their reduced volume. A roll of flat plastic film occupies a fraction of the storage space compared to pre-formed bubble wrap or loose-fill materials. This means more packaging material can be shipped to the warehouse in a single truckload, reducing transportation-related emissions.

Furthermore, when used correctly, air pillows provide excellent cushioning and product stability. While traditionally made from plastic, the market is rapidly shifting towards versions made from recycled content and, increasingly, recyclable film plastics that are part of store drop-off programs. Some advanced systems even allow for the pillows to be deflated and reused by the end customer for their own shipping needs, extending the material’s life.

#9 Smart QR Labels

A common failure in the recycling stream is “wish-cycling”—when well-intentioned consumers toss non-recyclable items into the bin, contaminating entire loads. Smart QR code labels are a simple yet powerful technological fix for this problem. By adding a unique QR code to the packaging, brands can directly guide consumers to the correct disposal method.

A quick scan with a smartphone can lead to a webpage that specifies, “This box is recyclable, but the inner film should be placed in the trash,” or “Find your nearest drop-off location for this type of plastic.” This direct line of communication empowers consumers, increases recycling rates, reduces contamination, and demonstrates that the brand’s responsibility extends all the way to the package’s end-of-life. It turns a moment of confusion into an engagement opportunity.

#10 Returnless Refunds

Often overlooked in the packaging conversation is the environmental cost of returns. Reverse logistics is a carbon-intensive process involving transportation, repackaging, and often, the disposal of lightly used or simply unwanted items. A growing number of retailers, particularly for low-cost items, are implementing returnless refunds or “keep-it” policies.

When a customer requests a return for a non-defective item, the company simply issues the refund and allows the customer to keep, donate, or responsibly dispose of the product. While this may seem counterintuitive from a financial perspective, the calculus is changing. When the costs of return shipping, processing, inspection, and potential repackaging are factored in, it is sometimes more economical and always more sustainable to avoid the return altogether. This policy saves fuel, labor, and packaging, and it enhances customer goodwill by providing a seamless, hassle-free resolution.

Conclusion: Sustainable Packaging into a Cohesive Strategy

The journey toward truly sustainable e-commerce packaging is not about choosing a single silver bullet from the list above. The most successful brands will adopt a holistic strategy, weaving together multiple innovations that align with their specific products, customer base, and operational capabilities. This might involve using a recycled cardboard box printed with plant-based inks, cushioned with starch-based peanuts, and sealed with a seaweed-derived tape, all while educating the consumer via a smart QR code.

The underlying trend is clear: the future of e-commerce is circular, intelligent, and responsible. By investing in these sustainable packaging solutions, businesses do more than just protect the environment. They build resilient brands, foster deep customer connections, and position themselves as leaders in the new economy—one where value and values are inextricably linked. The unboxing experience is no longer just about revealing a product; it’s about unveiling a company’s core principles.

Like this article?

Read our e-commerce blogs for more insightful content.

Frequently Asked Questions on Sustainable Packaging

1. What is sustainable packaging?

Sustainable packaging refers to materials and packaging designs that minimize environmental impact throughout their life cycle—from production to disposal. The goal is to reduce waste, carbon footprint, and reliance on non-renewable resources while maintaining functionality and product protection.

Sustainable packaging typically:

- Uses recyclable or compostable materials,

- Minimizes excess layers,

- Supports easy disposal or reuse, and

- Has a lower environmental impact compared to traditional packaging.

Examples include paper-based alternatives to plastic, biodegradable films, and reusable containers.

2. What are the 7 R’s of sustainable packaging?

The 7 R’s of sustainable packaging provide a framework for creating environmentally responsible packaging systems:

- Rethink – Reconsider the design and necessity of packaging.

- Refuse – Eliminate unnecessary materials or single-use components.

- Reduce – Use fewer resources without compromising product protection.

- Reuse – Design packaging that can be used multiple times.

- Recycle – Opt for materials that can easily re-enter the recycling stream.

- Replace – Switch to eco-friendly alternatives (e.g., paper instead of plastic).

- Rethink/Recover – Innovate new ways to reclaim or repurpose used packaging.

This approach pushes brands to move beyond single-use plastics and consider the entire packaging life cycle.

3. What is the most sustainable way of packaging?

The most sustainable packaging minimizes environmental harm by focusing on reusability, recyclability, and material efficiency. Examples include:

- Compostable packaging made from plant-based materials like cornstarch or sugarcane.

- Minimalist packaging that eliminates excess layers, inks, and adhesives.

- Refillable containers that extend the product’s life cycle.

- Recyclable paper or glass over mixed plastics that are hard to process.

The best solution often depends on the product category, logistics, and the local recycling infrastructure.

4. What are the 4 types of packaging?

The four main types of packaging used in retail and e-commerce are:

- Primary Packaging – The material that directly holds the product (e.g., a bottle for shampoo).

- Secondary Packaging – Groups primary packages together for branding or protection (e.g., a branded box).

- Tertiary Packaging – Used for bulk handling and shipping (e.g., pallets, stretch wrap).

- Quaternary Packaging – Large-scale distribution packaging used in logistics and warehousing.

When applying sustainable practices, each of these layers can be optimized to reduce waste, improve recyclability, and minimize carbon emissions.